Retrofit - Machine modernization

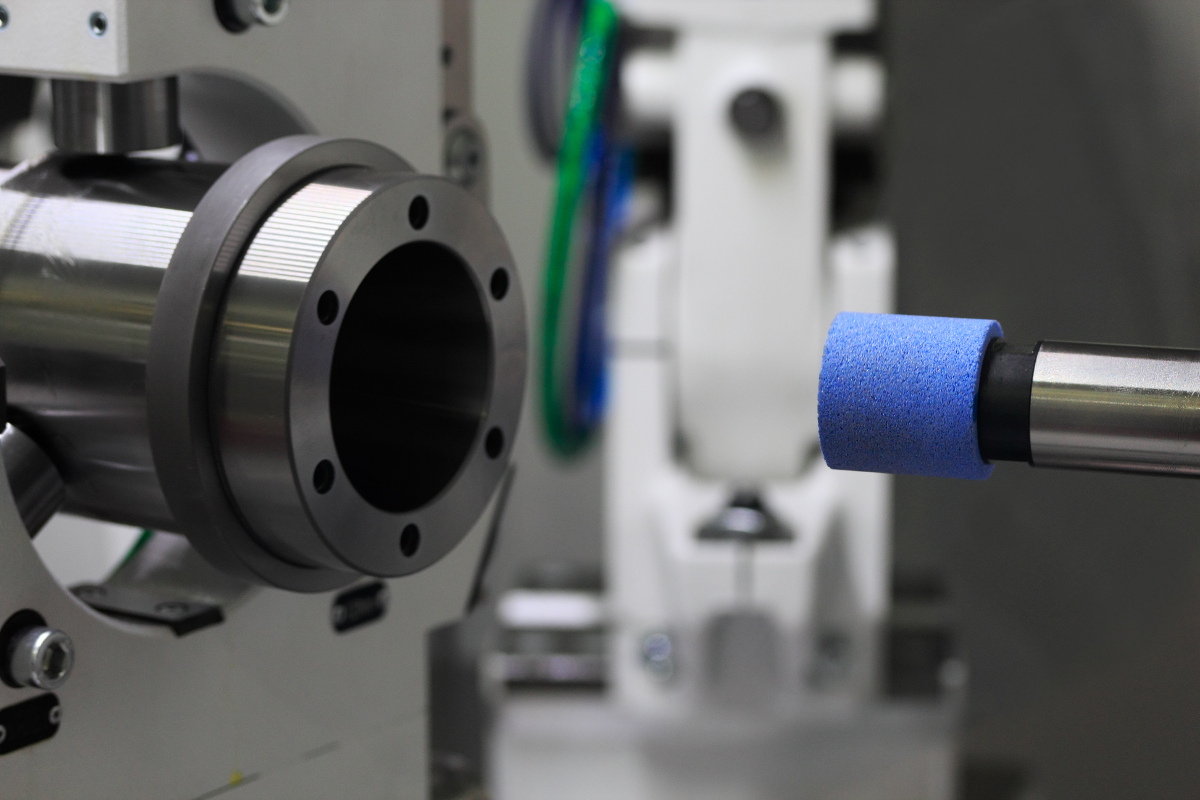

The mechanical condition of older machine tools is usually still good to very good, but the control components, some of which are beyond repair, prevent the machine from operating reliably. In these cases, the machine can be given a new lease of life by means of a complete electrical modernization with a FANUC CNC controller.

With the latest generation of FANUC CNC controls, the modernized tool grinding machine can also do everything a new machine can do: Prevent air grinding using the latest structure-borne sound technology, workpiece inspection and setup using touch probes, integration of balancing systems, display and monitoring of process sensors (temperatures/flows/force sensors/etc.), connection of the control to the local network, Industry 4.0 applications, and and.... There are no limits to the possible range of functions for your machine tool!

Thanks to the worldwide distribution network and the extremely long availability of FANUC spare parts, the machine can be operated in a more fail-safe and future-oriented manner.

We develop and create for you…

Conception

- Control system design

- Electrical diagram

- Operation

Mounting and wiring

- Electric cabinet

- Control panel

- Electrical connections in and on the machine

- Modernization of sensors, actuators

Software development

- Basic software

- HMI - user interface

- Machining cycles and NC programs

- Customized software