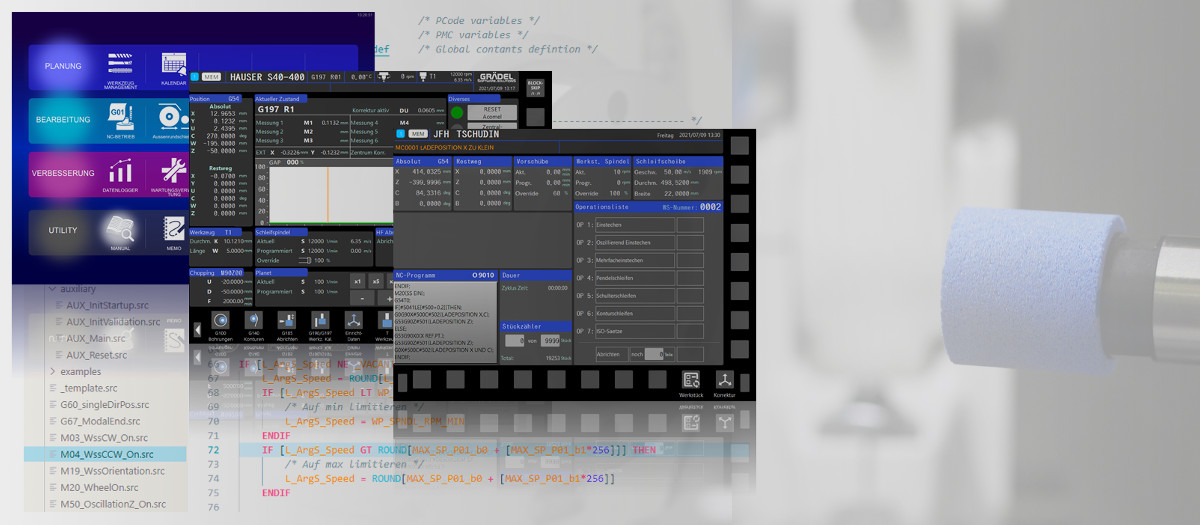

Retrofit HAUSER with FANUC CNC control system

We are specialized in retrofit of HAUSER jig grinders and have developed a user software compatible to the older HAUSER machines based on the latest FANUC CNC controls and developed a modular electrical concept. Thanks to our many years of experience, we can offer you a professional retrofit of HAUSER grinding machines and support you with questions or problems in all areas related to jig grindin

In close cooperation with FANUC Switzerland, we install the latest FANUC CNC controls with integrated safety. Thanks to our experience, we create the electrical design and machine software completely ourselves and are therefore able to respond to customer requests.

With the latest generation of FANUC CNC controls, a modernized HAUSER can also do many things that a new machine can: Prevent air grinding using the latest structure-borne sound technology, workpiece inspection and setup using probes, display and monitoring of process sensors (temperatures/flow rates/force sensors/etc.), connection of the control to the local network, Industry 4.0 applications, and and and.... There are no limits to the possible range of functions!

We install the latest FANUC CNC controls, create a new electrical cabinet and replace the cables on the machine, modernization of the pneumatic and hydraulic system, mechanical revisions where necessary and useful, new painting if desired.

Repairs & diagnosis

Do you have problems with your machine? We are specialized in the diagnosis of sporadic electrical phenomena. We also offer repairs and revisions of electrical and mechanical components.

Problems with the electronics? We have various used control components in stock. We can repair your stroke controller (SHZ/NHZ), multi-sensor device (MSS1/MSS2/MSS3), HAUSER axis controller or ACOMEL frequency converter.

Maintenance & spare parts

Are you looking for an alternative provider to professionally perform maintenance on your jig grinding machine? We can help you. In addition to standard maintenance work, we can also perform U-axis revisions and geometry measurements. All installed spare parts are original parts or in at least equivalent quality.

You would like to optimize your machine with further expansion stages? Such as retrofitting HF dresser, pallet changer, structure-borne sound sensor system.

Software for FANUC CNC controls

With a FANUC CNC control system it is possible to implement the software exactly for its purpose. In this case, the integrated machine software is supplemented with the software components developed by us: control and monitoring of the periphery, parameterizable machining sequences and its visualization.

Our experience with the various software components in the CNC control system enables us to develop the optimal customer-specific solution.

Retrofit - Machine modernization

The mechanical condition of older machine tools is usually still good to very good, but the control components, some of which are beyond repair, prevent the machine from operating reliably. In these cases, the machine can be given a new lease of life by means of a complete electrical modernization with a FANUC CNC controller.

With the latest generation of FANUC CNC controls, the modernized tool grinding machine can also do everything a new machine can do: Prevent air grinding using the latest structure-borne sound technology, workpiece inspection and setup using touch probes, integration of balancing systems, display and monitoring of process sensors (temperatures/flows/force sensors/etc.), connection of the control to the local network, Industry 4.0 applications, and and.... There are no limits to the possible range of functions for your machine tool!

Thanks to the worldwide distribution network and the extremely long availability of FANUC spare parts, the machine can be operated in a more fail-safe and future-oriented manner.